Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

When it comes to selecting the right ball bearing slide for your application, one of the most critical yet often overlooked factors is usage frequency. Whether a slide will endure constant, daily operation or only occasional access can dramatically influence its required durability, load capacity, and overall design. Choosing the wrong slide based on usage patterns can lead to premature wear, increased maintenance, and even system failure. Let’s explore how the frequency of use impacts your slide selection process.

1. High-Frequency, Daily Use Applications

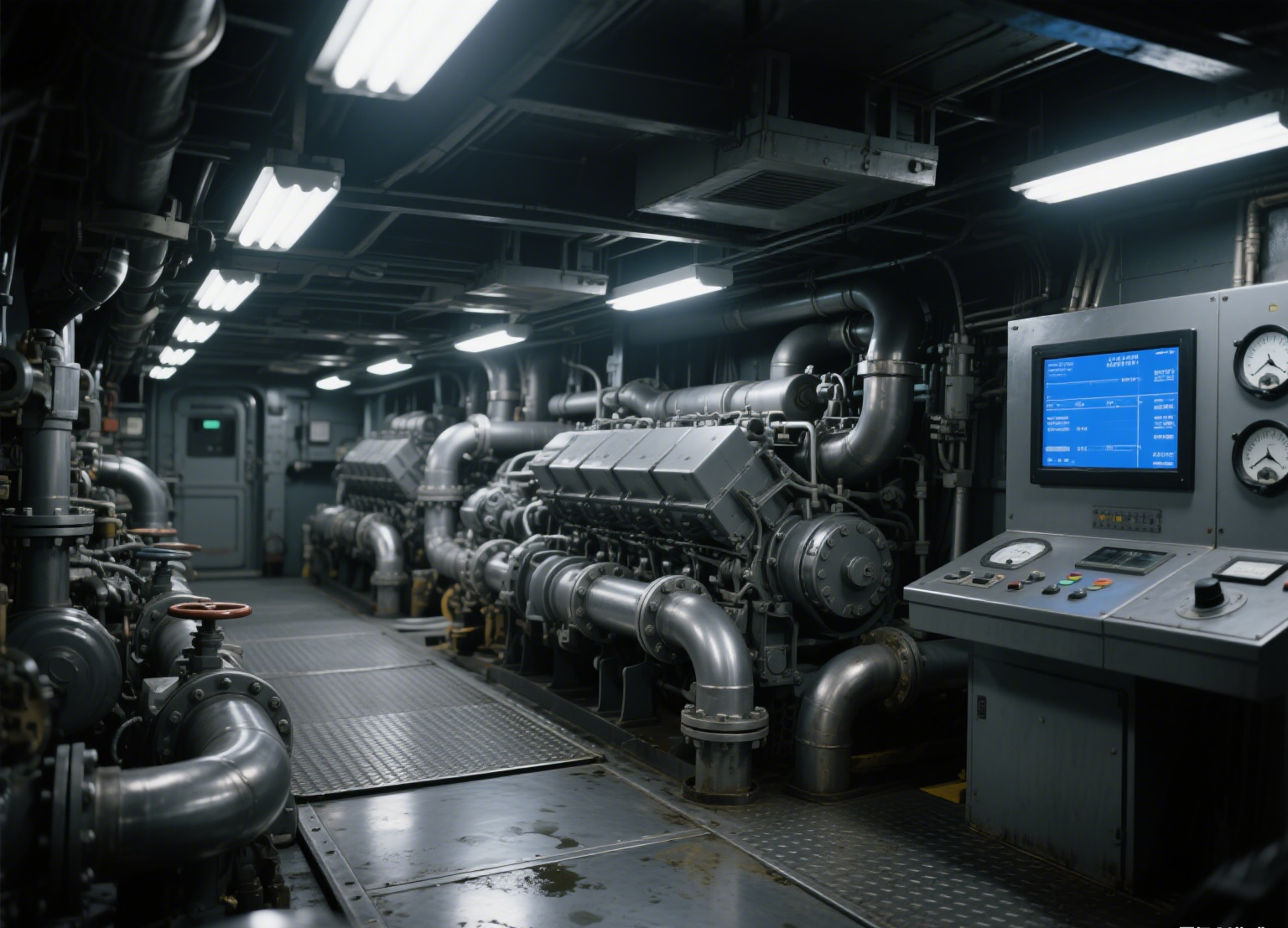

If your slide will be opened and closed multiple times a day, every day—such as in industrial machinery, medical equipment, server racks, or commercial kitchen drawers—durability and precision are paramount.

Example: In a hospital imaging machine, where a technician accesses internal components multiple times per shift, a high-cycle, corrosion-resistant slide ensures reliability and minimizes downtime.

2. Low-Frequency, Occasional Access Applications

For applications like emergency access panels, storage enclosures, or backup equipment drawers that may only be opened a few times a year, the priorities shift.

Example: In a data center’s backup server cabinet, a slide used only during maintenance cycles benefits from corrosion resistance and a positive locking feature to secure components when not in use.

Conclusion

Understanding how often a slide will be used is a fundamental step in making the right selection. High-frequency applications demand robust, precision-engineered slides built for endurance, while low-frequency uses prioritize longevity during inactivity and cost efficiency. By aligning your slide choice with actual usage patterns, you ensure optimal performance, reduce lifecycle costs, and enhance user satisfaction.

Choose wisely—your slide’s lifespan depends on it.